IntelligentSupplySensing

Centralized supply chain illumination to provide actionable risk mitigation

Role

UX/UI Designer

Research

Information Architecture

Interaction Design

Deliverables

Wireframes

Journey Maps

Interactive Prototype

Overview (brief)

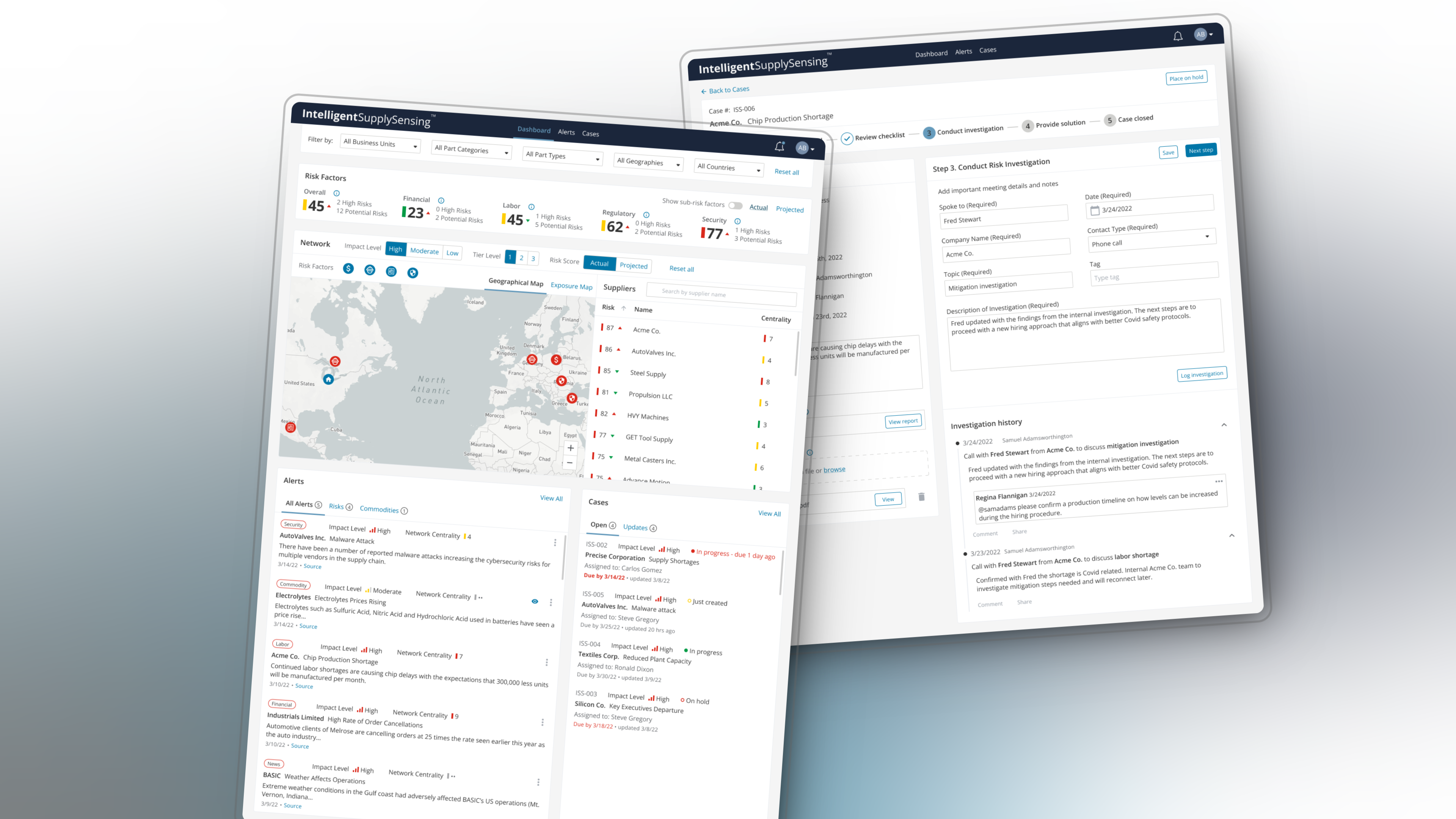

Our consultants collaborated with a journey client to address the vulnerability of their supply chain where disruptions can have severe consequences for businesses, ranging from production delays to revenue losses. The primary goal was to design an application that provides visibility into multiple tiers of their supply chain using AI/ML data sources to track and asses risks while providing analytical risk indicators, allowing them to proactively identify and mitigate potential disruptions.

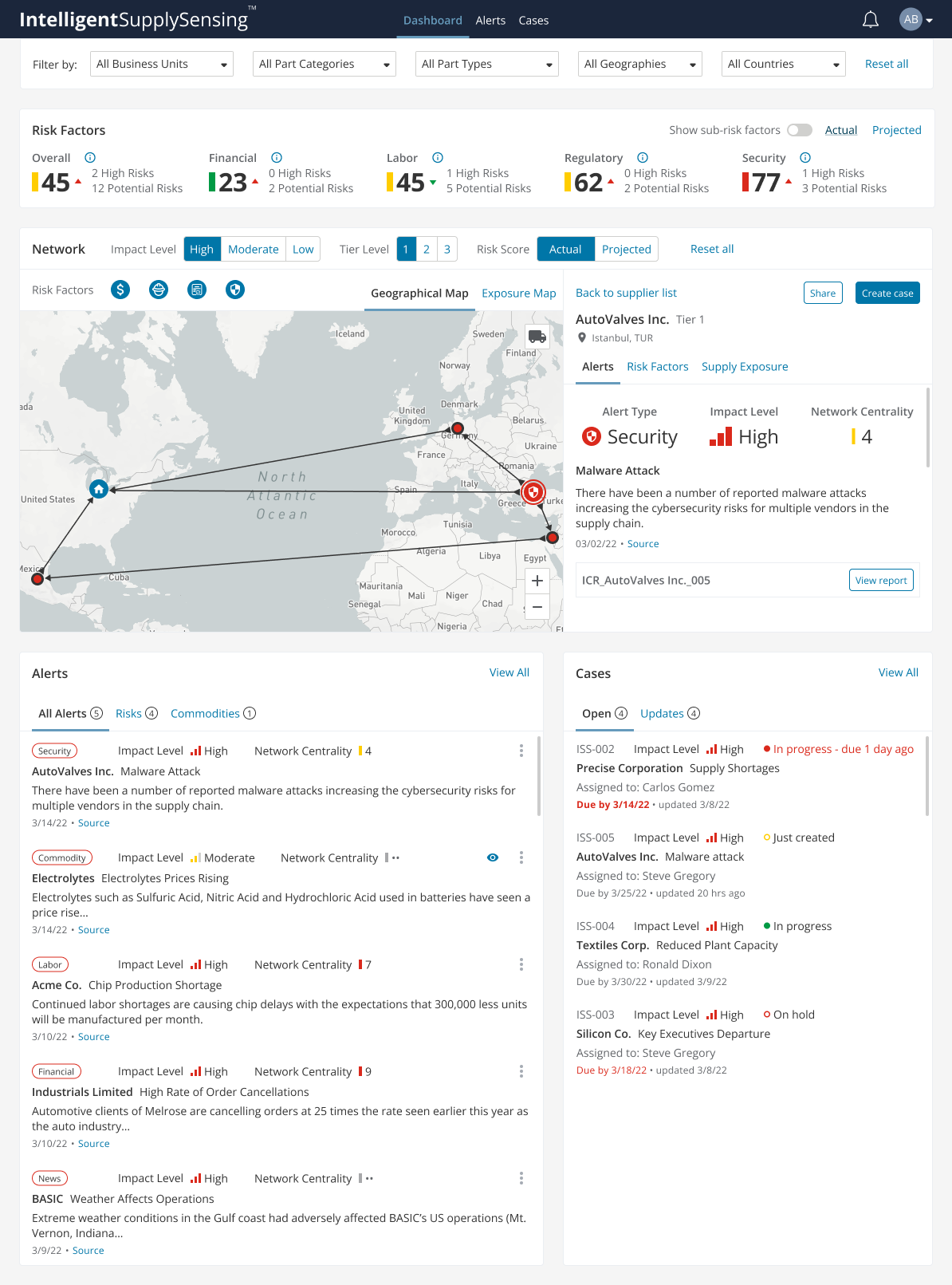

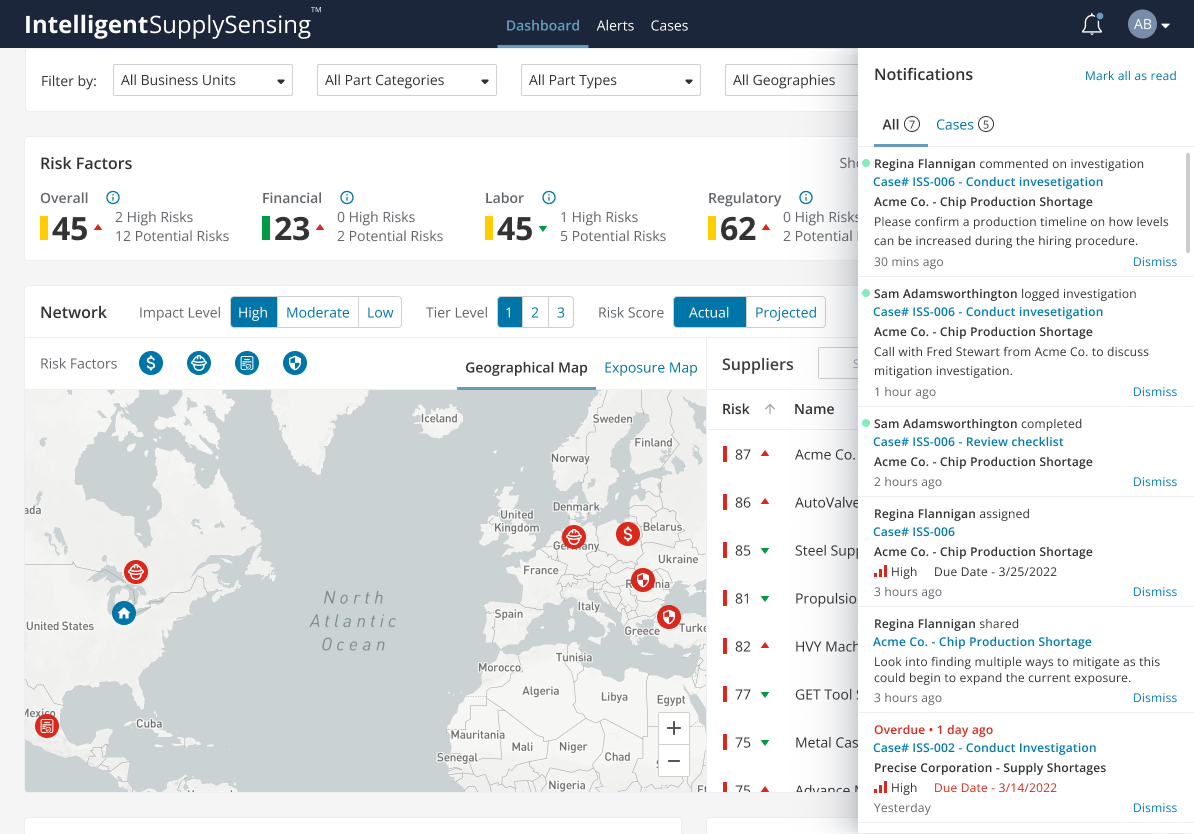

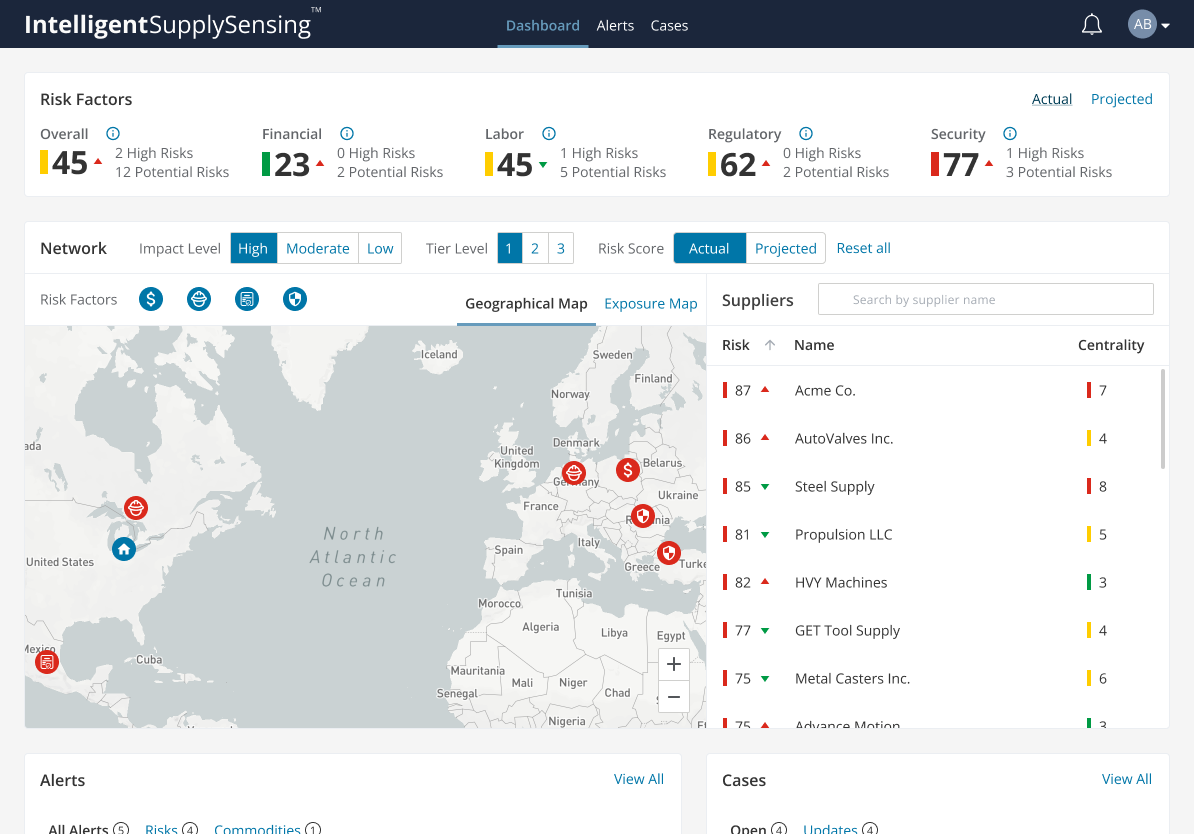

Dashboard showing supply chaain risk factors and alerts within global map.

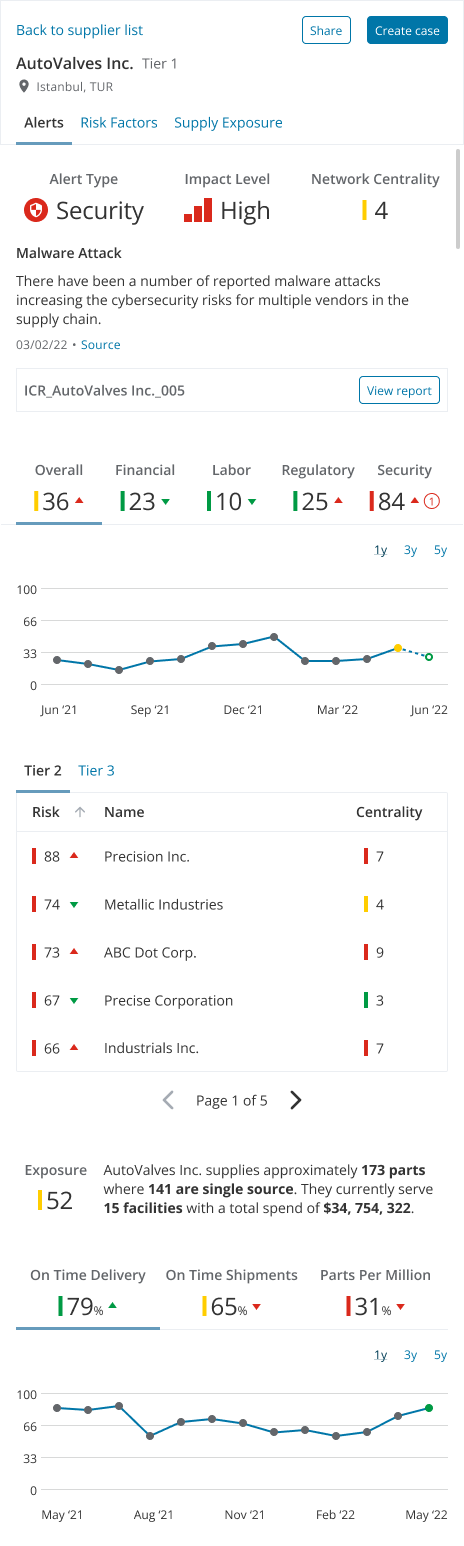

Supplier panel that details the alert, risk factors, tiers, and exposure of the selected high risk suplier.

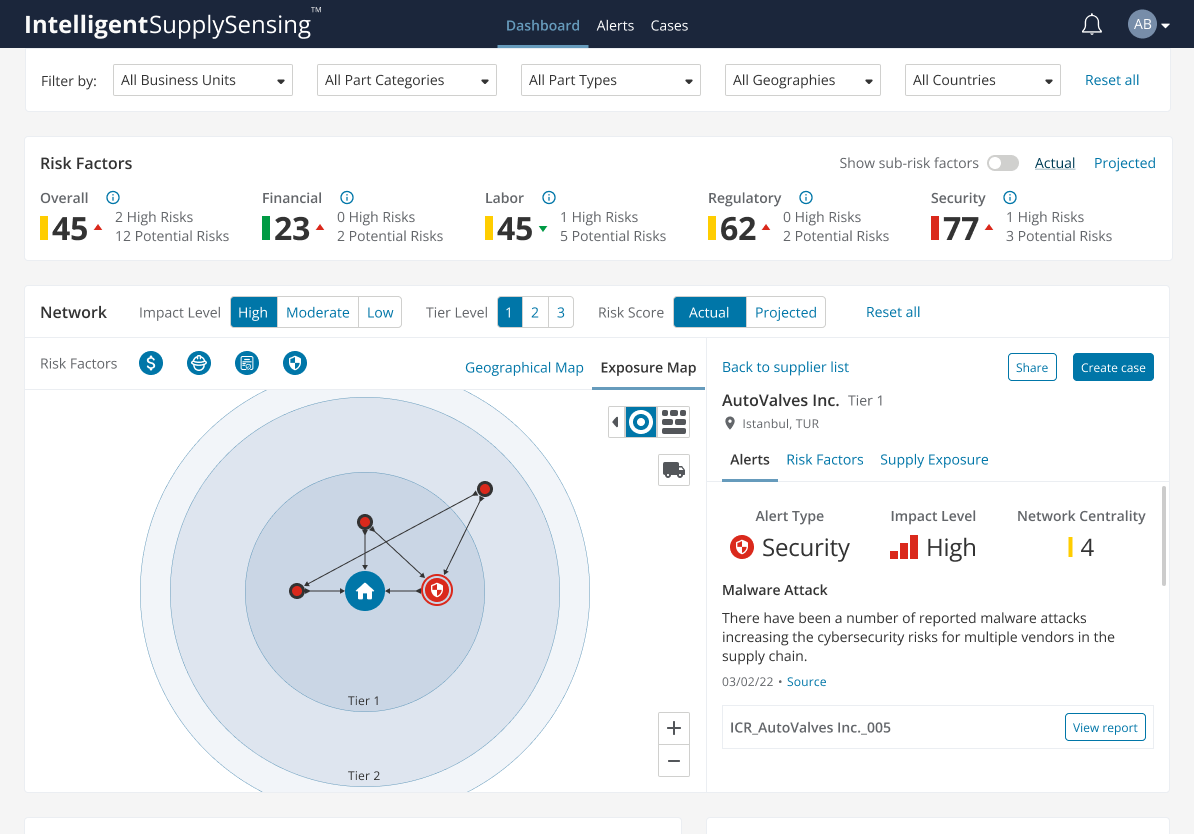

Dashboard with the tiered radail exposure map view for a high risk supplier.

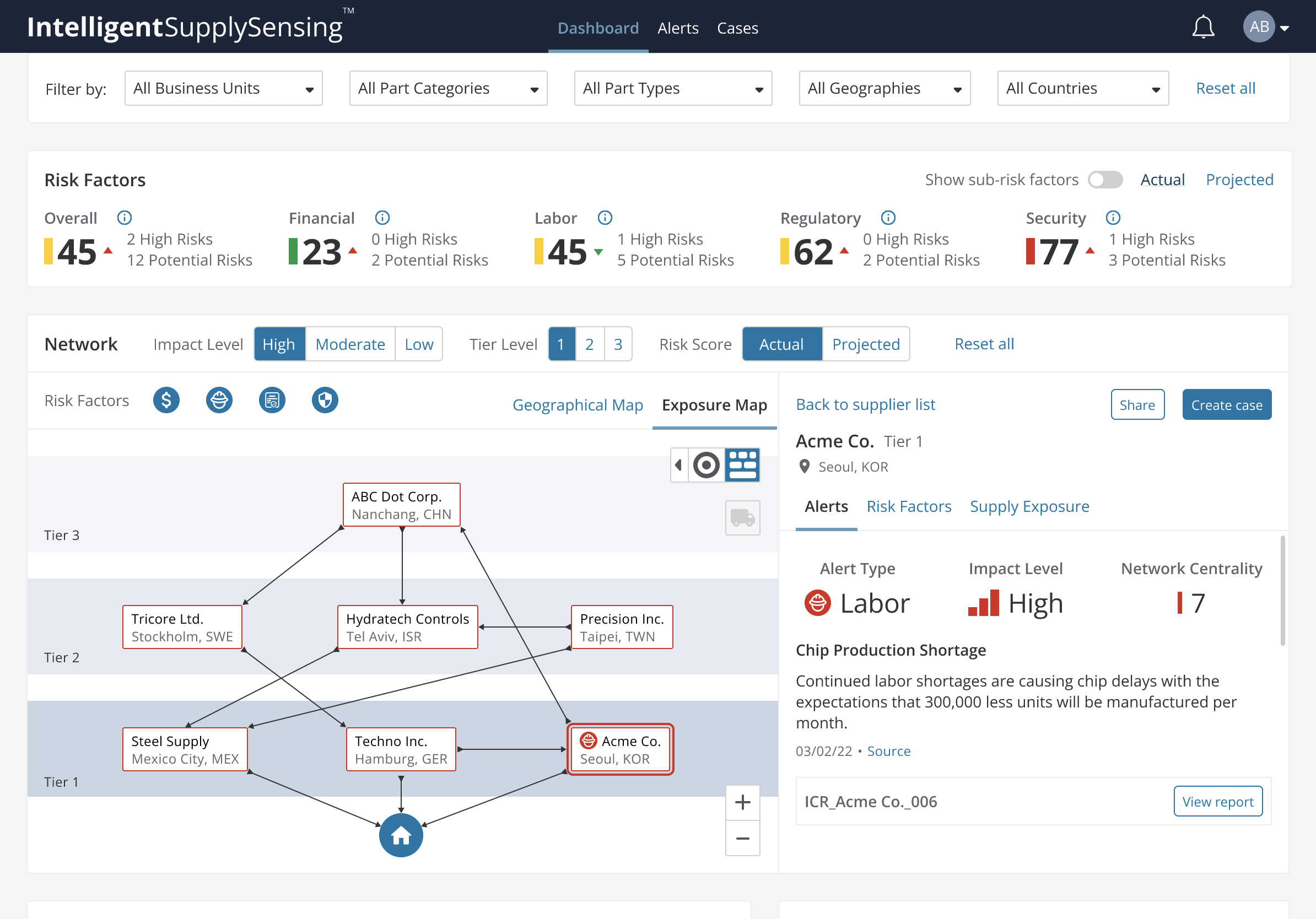

Dashboard with the stacked tier exposure map view for a high risk supplier.

Notifications panel dispalyed when selecting the notification icon in the global header.

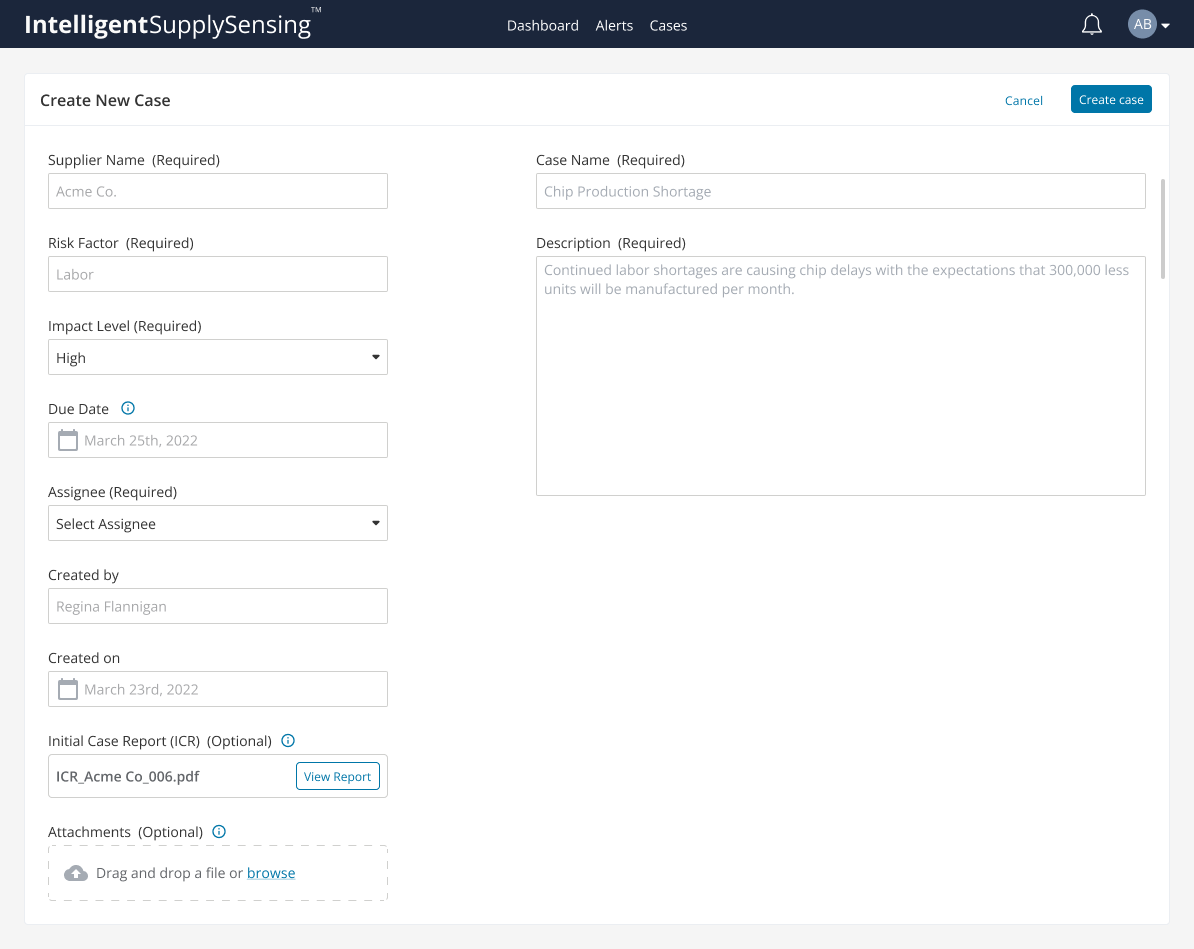

Create new case page allows the user to set all the prelimanry details for opening a case for an alert.

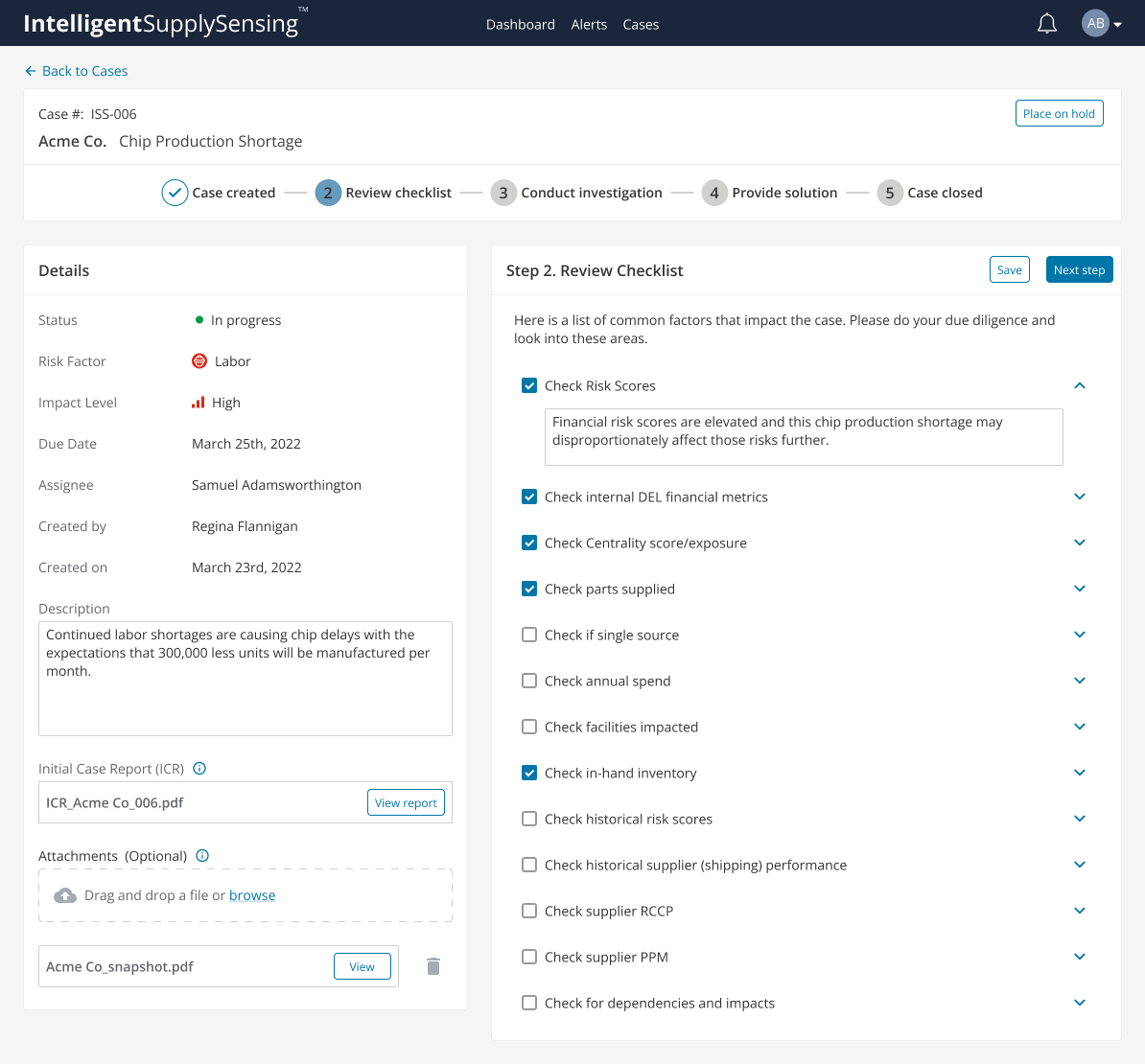

Case management review checklist step.

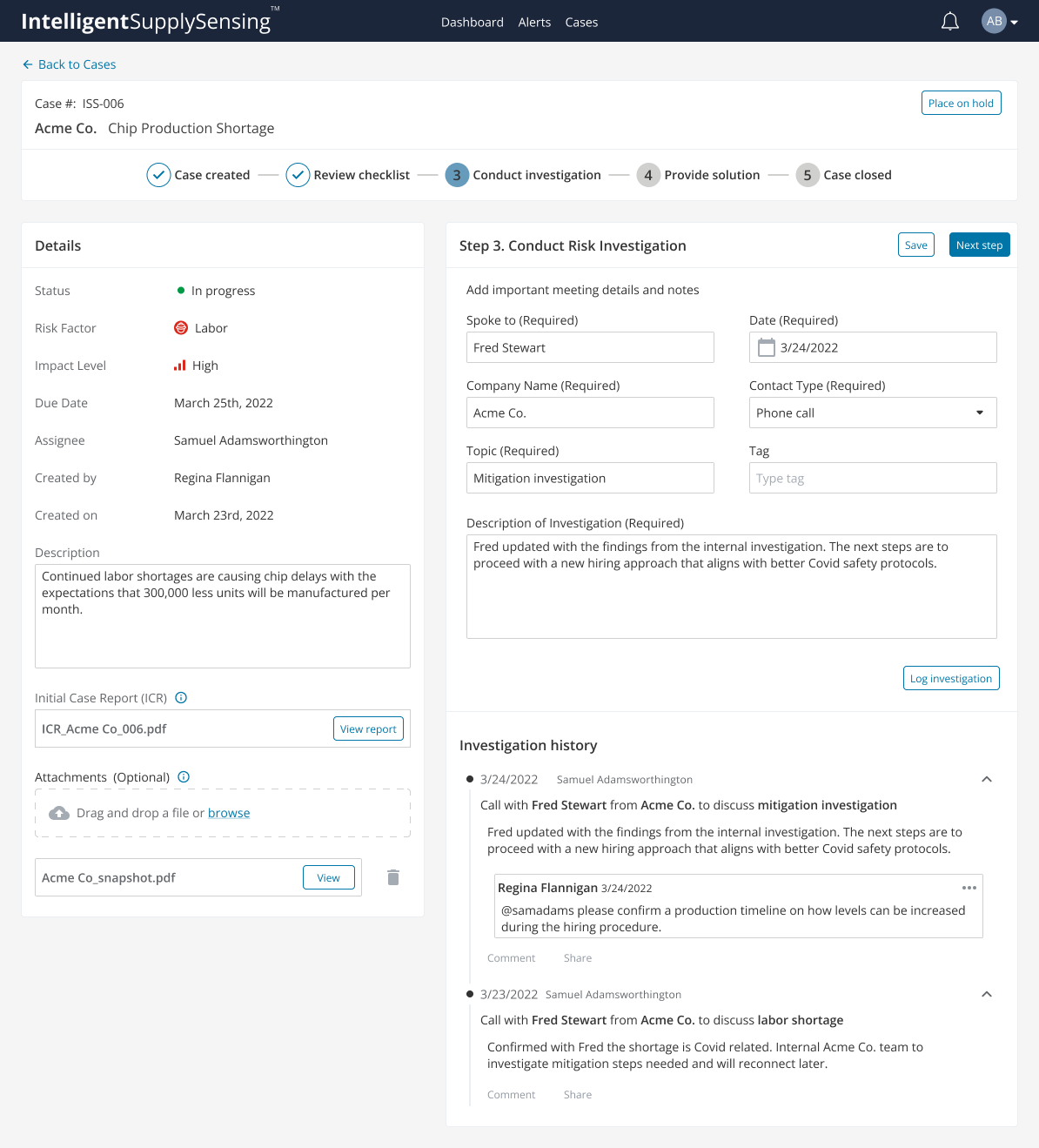

case management conduct investigation step to leg steps taken to mitage the risk.

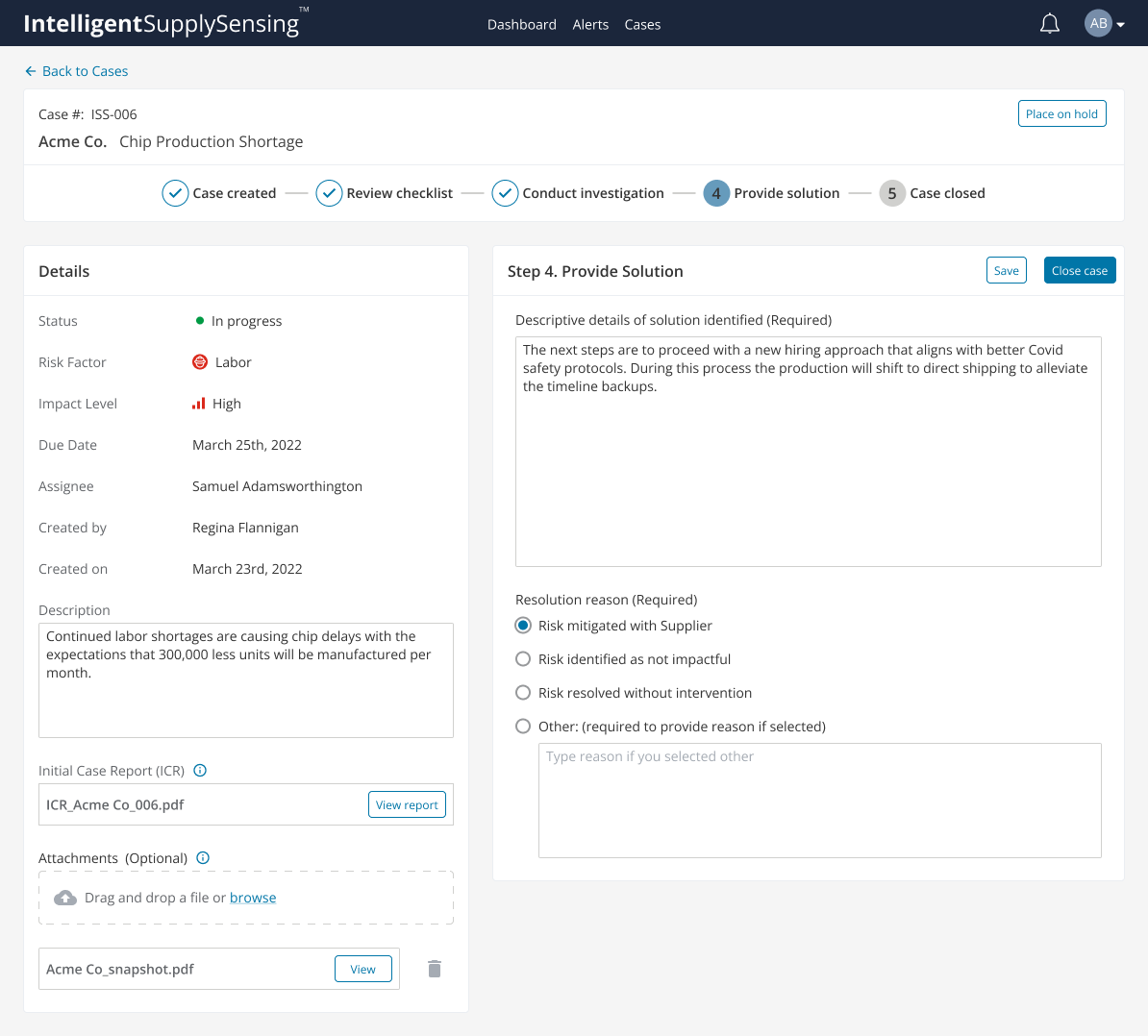

Case management provide a solution summary of how the risk was mitigated.

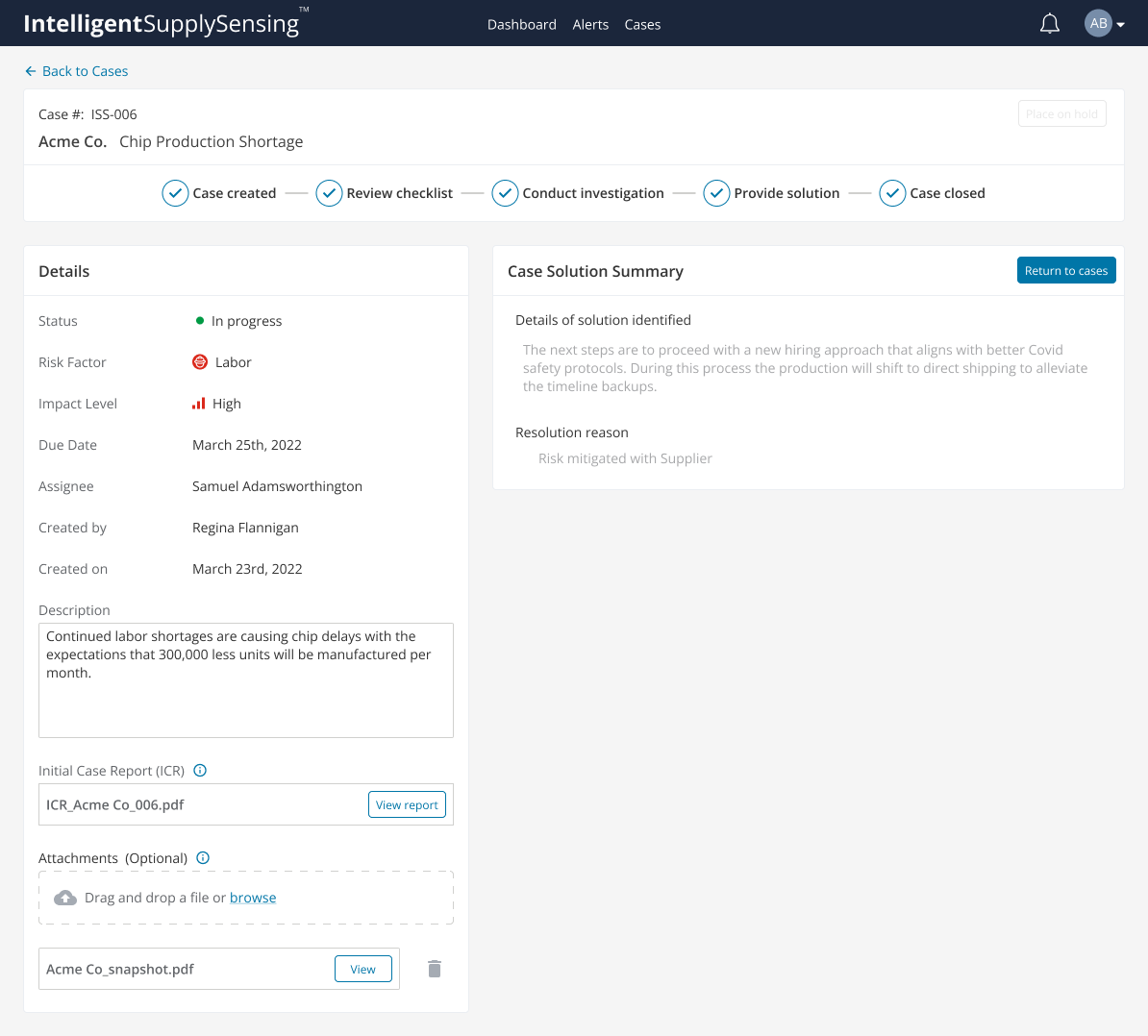

Case management case closed page that provides a read-only view of the solution summary.

Challenge

Traditional supply chain management methods often rely on manual processes and reactive approaches, making it difficult to anticipate and respond effectively to disruptions. Additionally, monitoring vast amounts of unstructured data from various sources to identify potential risks can be overwhelming and prone to human error.

I was the sole UX designer on this project and had 6 months to deliver a zero-1 MVP design. Working with a team that included a project manager and a few SMEs, I was tasked with collecting and analyzing over a year's worth of consultant research and prior concepts, assemble these pieces of the puzzle, and devise a solution to solve these pain points through an intuitive centralized supply chain illumination platform that could seamlessly integrate data, analytics, and provide actionable insights to proactively mitigate supply chain risks.

Design principles

To guide the design process and ensure alignment with user and business goals, I established the following principles:

Proactive Risk Mitigation: Empower users to identify and address potential disruptions, minimizing impacts on production and operations.

Data-Driven Insights: Leverage AI/ML capabilities to analyze and extract valuable insights that inform risk assessment and mitigation strategies.

Transparency and Visibility: Provide a comprehensive view of the supply chain network, enabling users to understand potential exposure and dependencies.

Seamless Communication: Facilitate collaboration and coordination among stakeholders involved in risk mitigation efforts.

Hypothesis

With a AI/ML-driven platform that integrates data that provides real-time insights and advanced analytics, Supply Chain COE Managers can proactively identify and mitigate potential supply chain disruptions, reducing the impact on production and operations while enhancing overall supply chain resilience.

Product thinking the solution

Since we didn't have the opportunity to explore our problem space after our consultants provided the initial research, I organized a workshop for my team and I to take a product thinking approach to understand the jobs-to-be-done for our user personas. My goal was aimed to simplify the features, as there are many ways to overcomplicate an already complex domain. I had us concentrate only on the necessary features needed for this MVP, helping us eliminate unnecessary elements and focus on achieving the Supply Chain COE's goals.

This helped ensure we had a clear understanding of the problem we were solving and the needs of our target users. Leading us to conceptualize the needed features, preliminary data points, preliminary requirements, and user permissions.

Our problem-solution-fit

Vision (why) - Supply chains are increasingly complex and vulnerable to disruptions. Without a proactive and data-driven approach, organizations struggle to anticipate and mitigate these risks effectively.

Strategy (how) - By designing an AI/ML-powered platform that integrates data from multiple sources, provides real-time insights, applies advanced analytics, and facilitate the collaboration and communication between users performing mitigation strategies.

Goals (what) - Supply Chain COEs and team will be empowered through visibility into their entire supply chain network and elevated risk indicators to proactively identify and mitigate potential supply chain disruptions, reducing the impact on production and operations.

Discover essential data

To ensure the app displays the necessary data, we gathered insights from SMEs and through surveys and interviews with Supply Chain COE Managers. This informed our understanding of the most critical data points and functionalities required for them to complete their goals.

Key insights

Our research revealed several key insights that informed the design decisions:

- Supply Chain Visibility: Lack of visibility into potential risks across multiple tiers of the supply chain made it challenging to anticipate and mitigate disruptions proactively.

- Risk Monitoring: Early identification of potential risks was crucial to minimize disruptions and deploy timely mitigation strategies.

- Data Consolidation: Users struggled with the manual effort required to consolidate and analyze data from multiple sources, leading to potential oversights and delays.

- Impact Analysis and Risk Assessment: Understanding the cascading effects of potential supply disruptions and assessing supplier risk exposure was essential for effective decision-making and mitigation planning.

- Collaboration and Case Management: Fragmented communication channels and lack of proper guidance made it difficult to effectively manage and coordinate successful mitigation efforts.

Building for data and action

Based on our research and insights, I designed detailed wireframes and interactive prototypes to address the key challenges and meet the needs of our Supply COE Manager. The core features of the solution include:

- Supply Chain Risk Dashboard: A centralized dashboard that provides a comprehensive view of the entire supply chain network, highlighting potential risks and exposures across multiple tiers.

- AI/ML-Driven Risk Assessment: Leveraging advanced AI/ML capabilities, the platform continuously monitors and analyzes data from various sources, including news alerts, social media, internal reports, and more, to identify potential risk indicators.

- Real-Time Alerts and Notifications: Users receive real-time alerts and notifications when potential disruptions are detected, enabling proactive mitigation efforts.

- Case Management: A dedicated case management module allows users to track and manage identified risks, assign mitigation tasks, and collaborate with relevant stakeholders.

- Mitigation Strategies and Recommendations: The platform provides data-driven guidance for implementing effective mitigation strategies based on the identified risks and potential impacts.

- Collaborative Communication: Integrated ways to communicate and collaborate that facilitate seamless coordination among users involved in risk mitigation efforts.

Testing and further refinement

After we conducted a few collaborative workshops reviewing different interaction models we were ready to move forward with testing the model we felt performed best. I developed an interactive prototype for our SME to demo with our client. During these demos we allowed them to test the flow of evaluating a risk alert through creating and closing a case. These demos allowed us to receive useful feedback and gain valuable insights that led to several improvements, including:

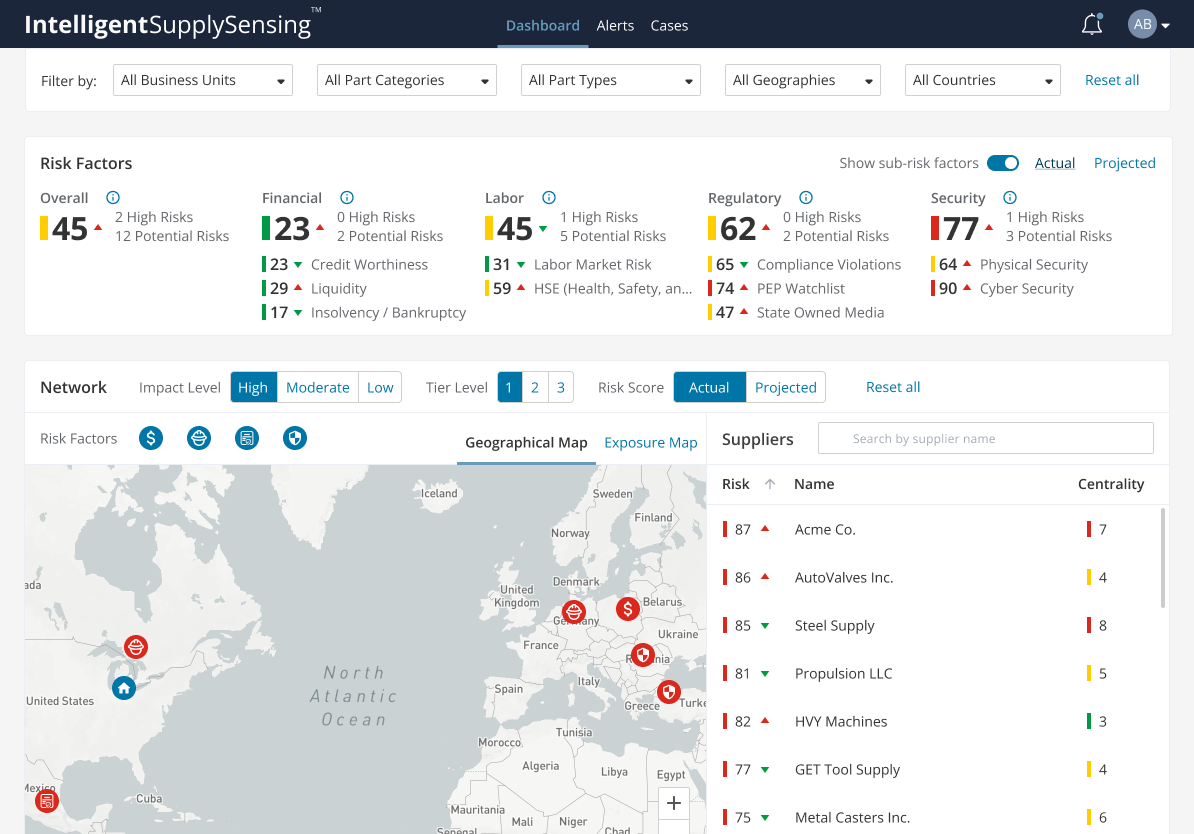

Expanding the risk factors on the dashboard to allow for more visibility into the sub-domains

Enhancing the dashboard with advanced filtering and sorting capabilities

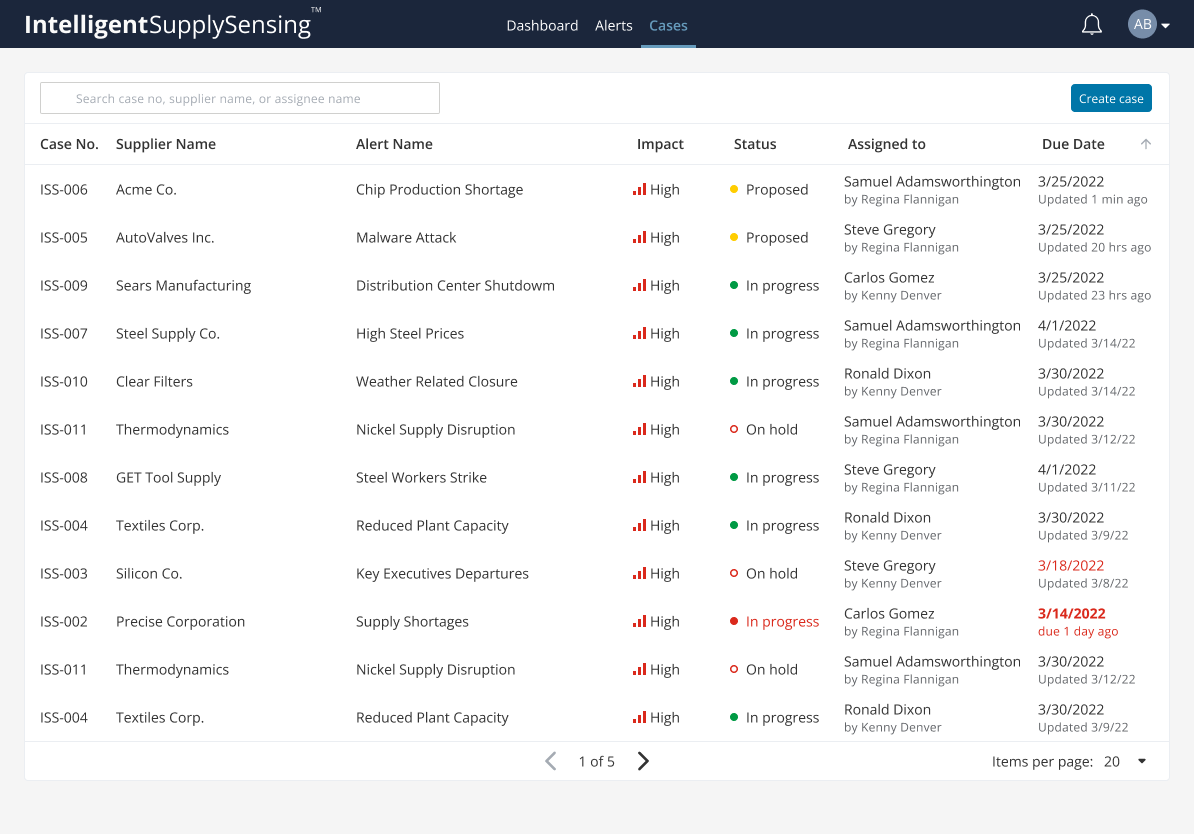

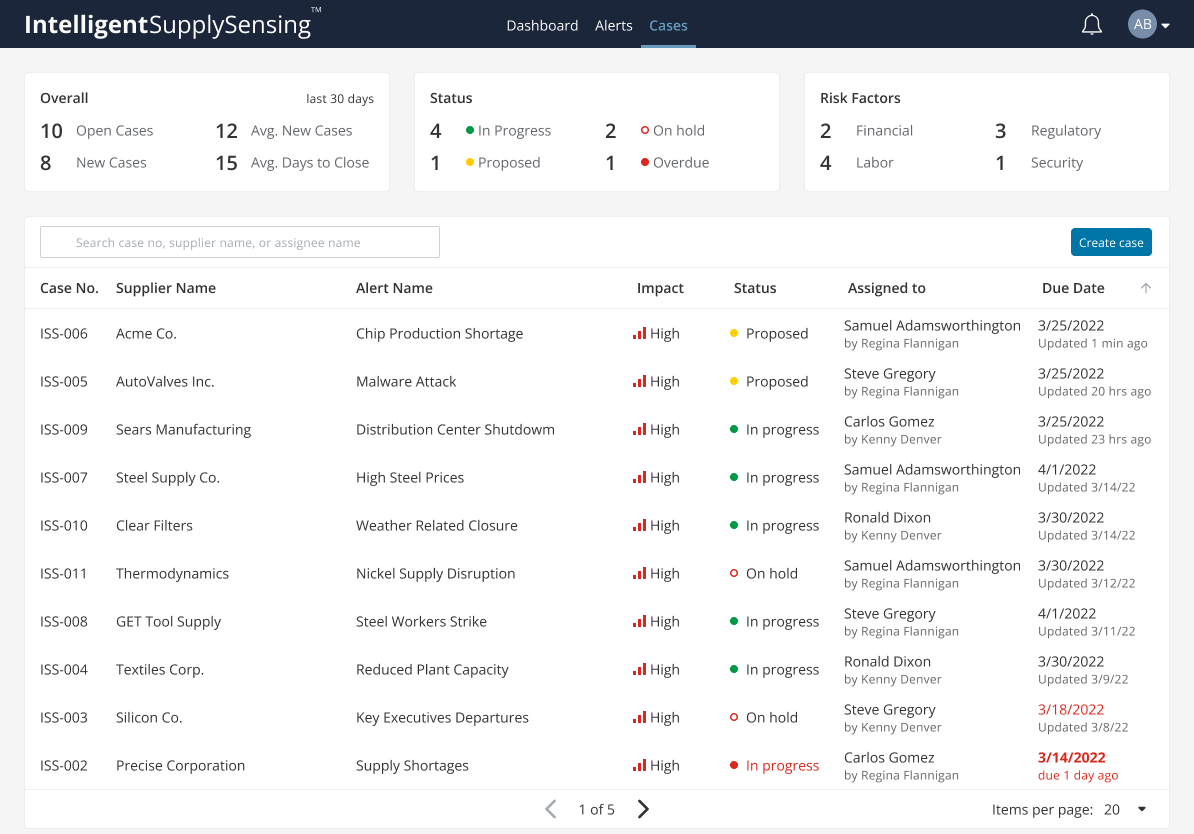

Improving the clarity around cases by adding case metrics to the cases page

Refining the case review check list (mitigation strategy recommendations) based on user feedback

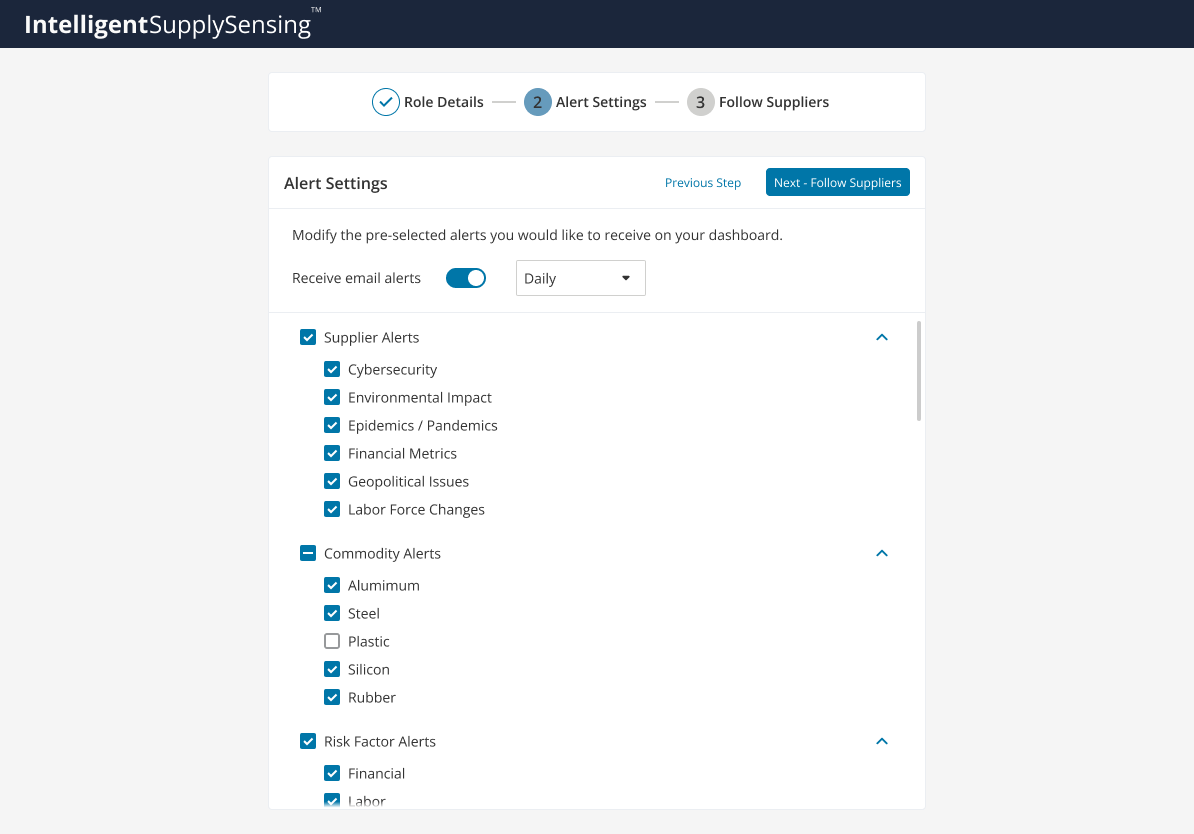

Introducing an onboarding setup that allows the user to specify the main alerts and suppliers they’d like to receive notifications for

Previous dashboard without filtering and the ability to expand the risk factors.

Advanced filtering and the expandability of the the risk factor sub-domains.

Case management page design without metrics.

Case management page enhanced with case metrics to improve clarity.

Refined case review checklist .

New onboarding setup allowing user to specify notifications to receive.

Outcome

After a comprehensive design process that involved product thinking, extensive research, iterative user testing, and continuous refinement, I was able to collaborate with my team and successfully deliver an MVP, an AI/ML-powered solution that empowers organizations to proactively identify and mitigate potential supply chain disruptions. With the features I delivered and more to come, this centralized platform has the potential to revolutionize supply chain risk management, enhancing supply chain resilience, minimizing the impact of disruptions on production and operations, and ultimately driving business continuity and success.